Laser Induced Deep Etching (LIDE)

High-aspect ratio microfeatures in glass for bio-applications

What is LIDE?

LIDE stands for laser induced deep etching:

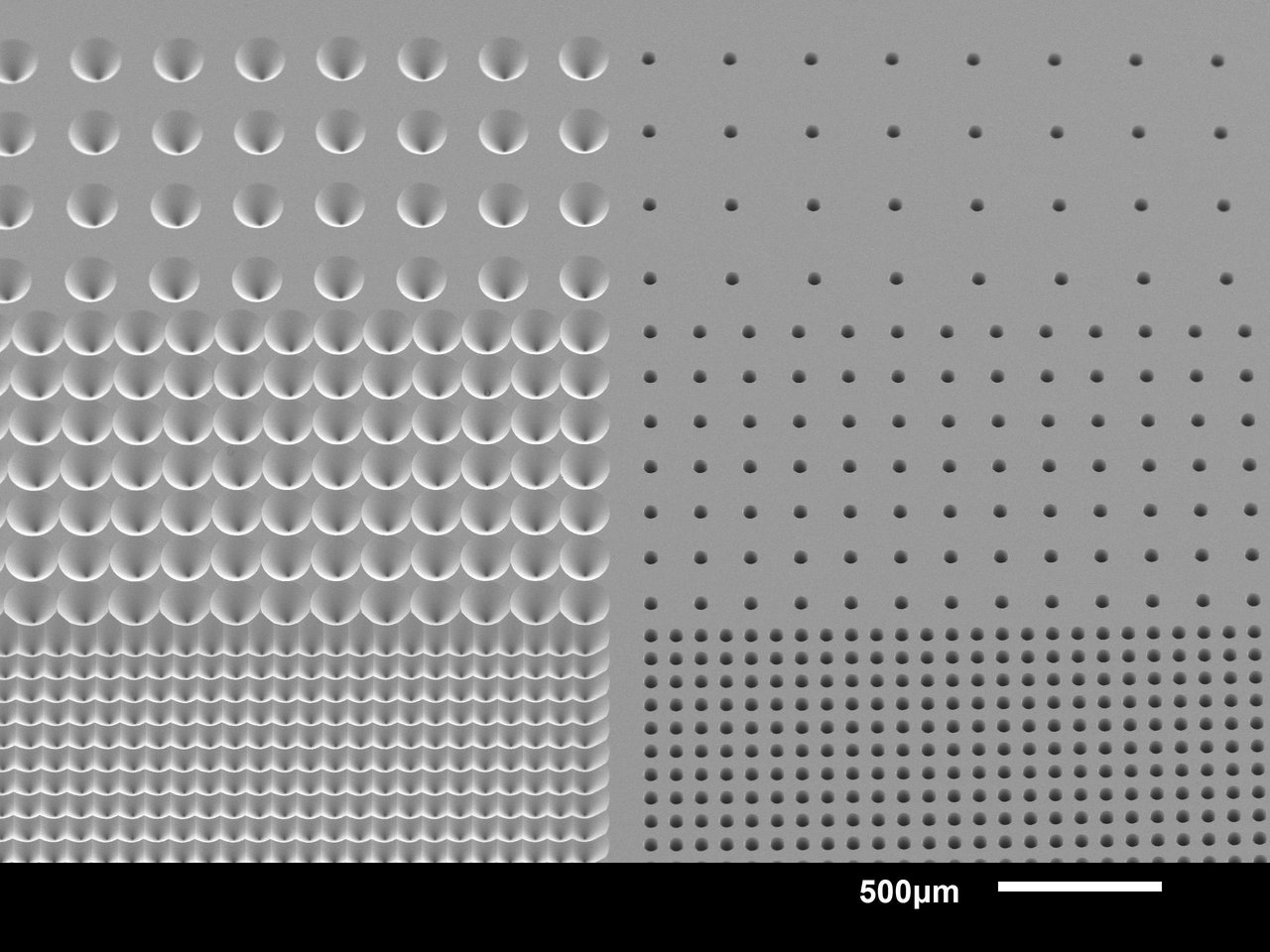

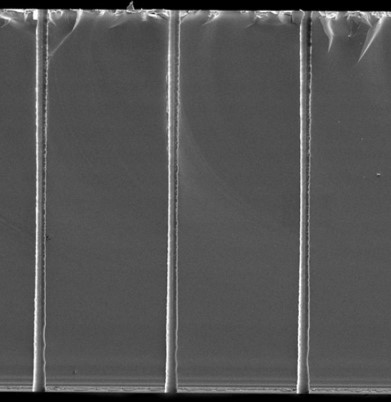

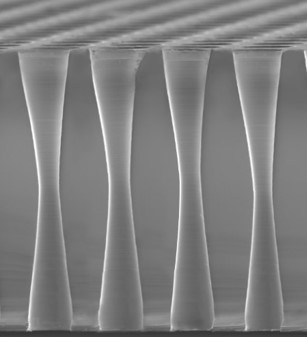

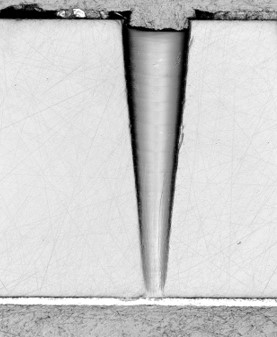

LIDE technology is a two-step process. It is characterized by the ability to create deep structures in thin glass with a high aspect ratio in the range of >1:10 at a highly-economical and groundbreaking processing speed. Structures as small as <5 μm can be created. Due to the precision of the LIDE process, picoliter well arrays (picowells), nanoliter well arrays (nanowells) as well as larger microliter well arrays (microwells) can be manufactured with the highest accuracy.

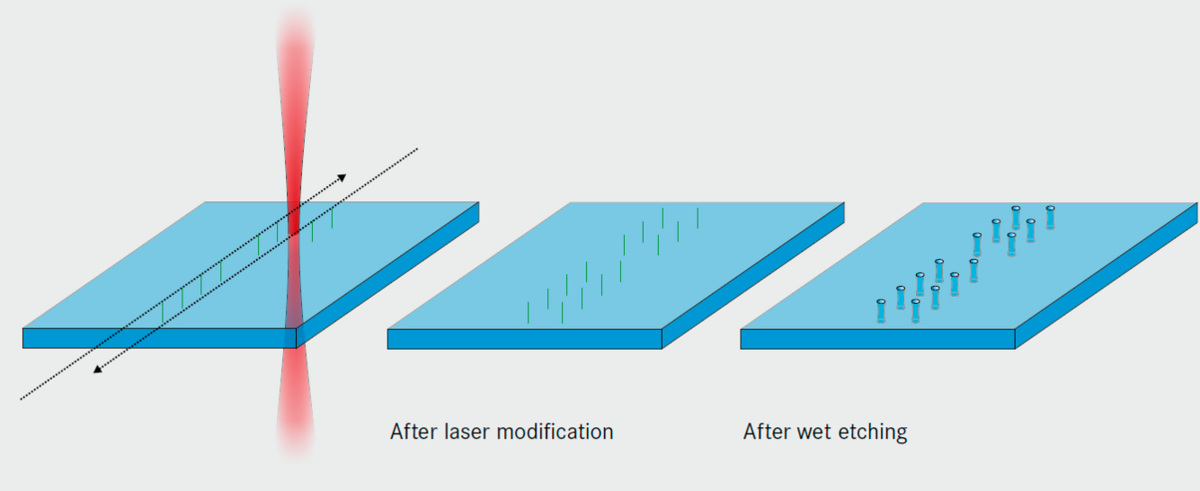

Step 1:

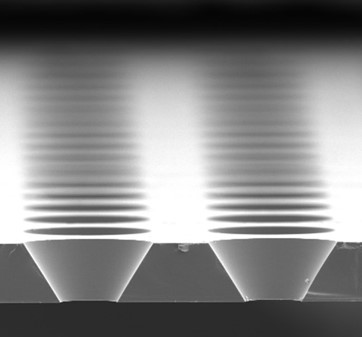

In the first step, the glass is locally modified by laser pulses according to the desired layout. In LIDE, a single laser pulse is sufficient to modify glass substrates through their entire thickness, making it compatible with high-volume production.

Step 2:

In the second process step, the modified areas of the glass are removed by wet chemical etching much more rapidly than the unmodified material.

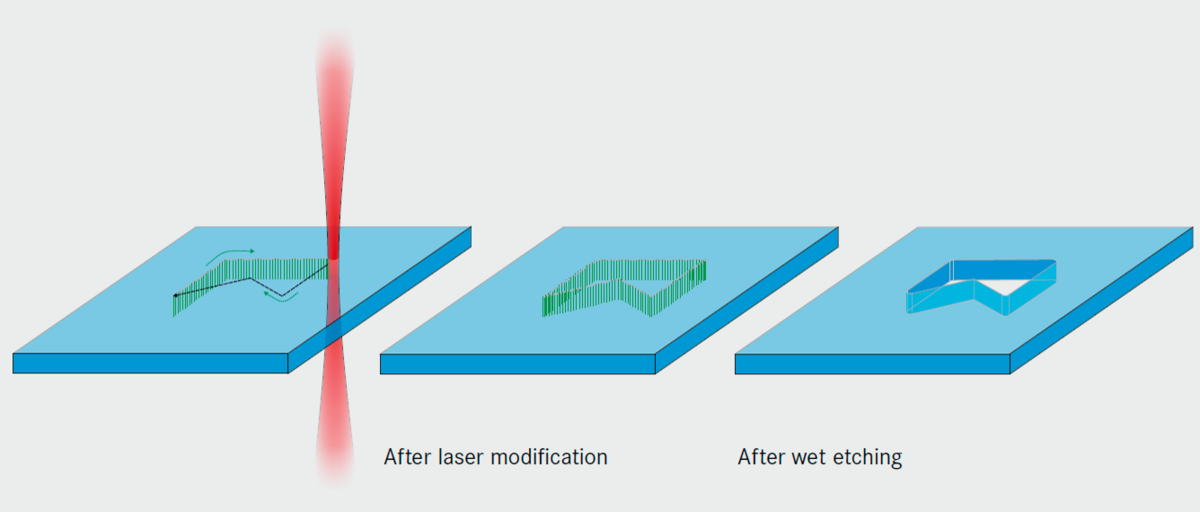

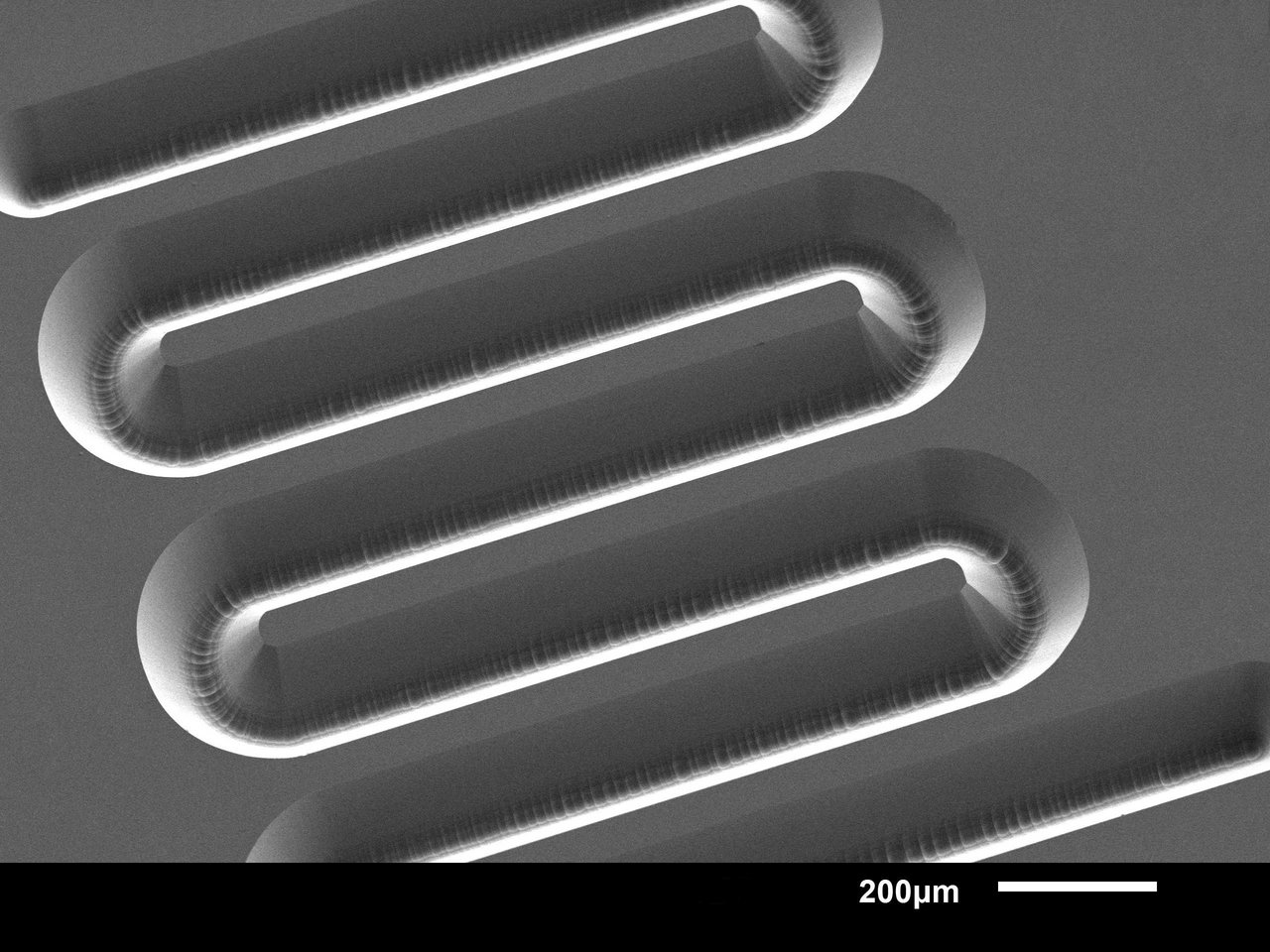

LIDE technology also makes it possible to introduce modifications into glass in a way that allows the cutting out of features in almost any shape and size.

With these characteristics, LIDE glass processing can be considered to be one of the most versatile techniques for the production of high quality microfluidic devices, bio-chips and arrays.

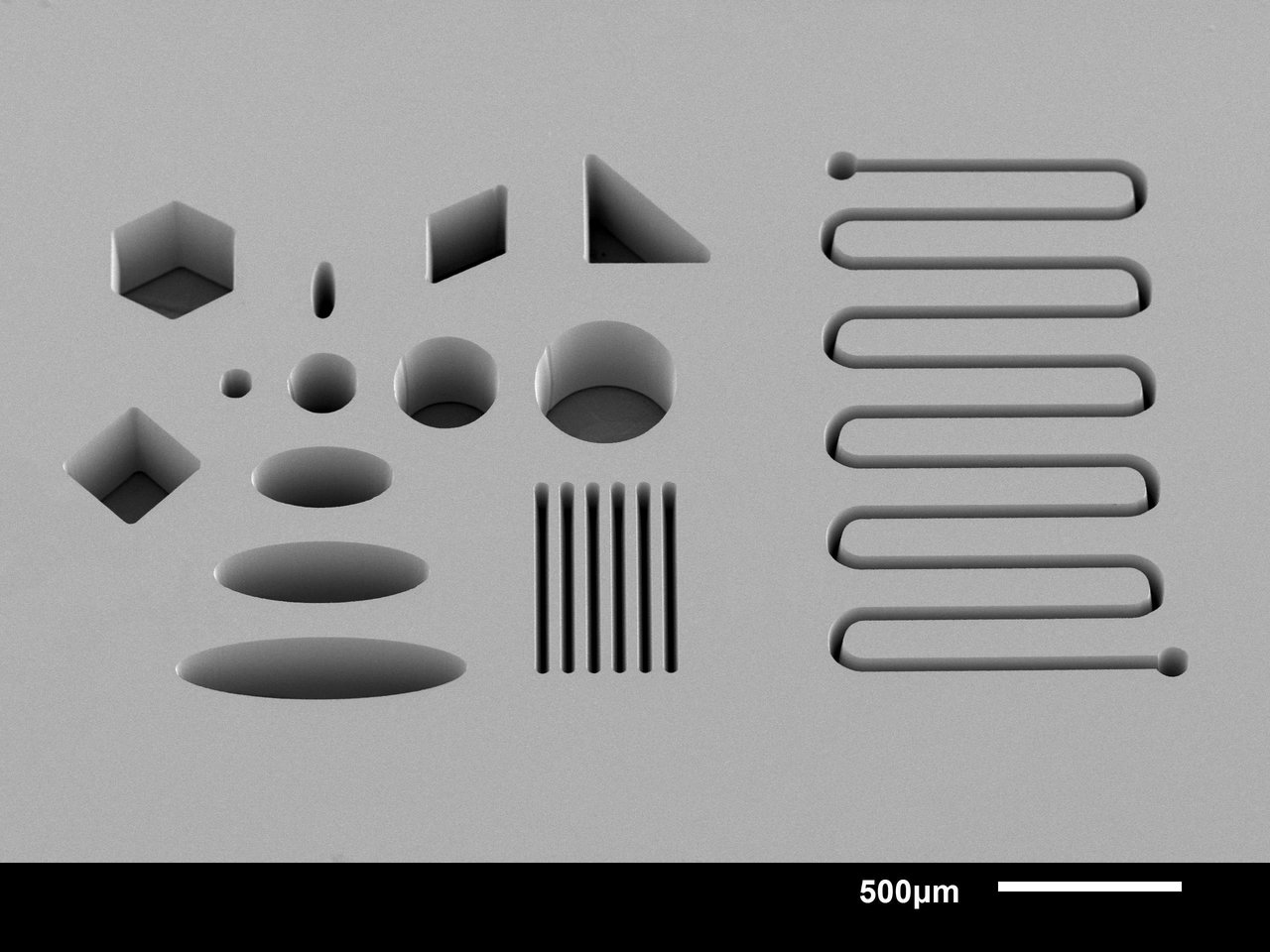

Some of the shapes that can be produced with LIDE are depicted below. Just contact us for an individual consultation of what is possible with LIDE in the field of microfluidic devices for biomedical and life science applications.

Outstanding characteristics of LIDE technology

LIDE does not rely on special glass. The technology is compatible with all commercially-available silicate-based glass types from different vendors.

LIDE technology is free of micro-cracks, chipping, induced stresses and the like. LIDE processing of glass does not diminish the good mechanical properties of glass, as seen in state-of-the-art glass-processing technologies.