Using Glass for Microfluidic Applications

The field of microfluidics is concerned with the behavior, precise control, and manipulation of fluids that are geometrically constrained to a small scale, typically in the sub-milliliter range. So it doesn’t come as a surprise that high standards to quality and reproducibility need to be applied when it comes to manufacturing microfluidic devices. In the field of life sciences microfluidics are mostly used for analytic purposes or to sort, transport or immobilize biologic material. Application examples range from genomics to functional single cell experiments.

The main materials to build microfluidic devices are, with few exceptions, limited to plastics, silicon or glass.

The realm of plastics allows to choose from a large variety of different sub-types, with both transparent and colored versions readily available. Besides the abundance of available plastic types, high volume manufacturing methods (such as injection molding) and the economics of plastics make this type of material the number one choice when it is possible to use it. However, when it comes to high precision manufacturing of small features, plastic loses its economic advantage quite fast. This becomes especially distinct for small features with high-aspect ratios that are hardly producible with injection molding. Polydimethylsiloxane - or PDMS for short - is an organic polymer that can be formed into various shapes without expensive tooling or processes, and therefore has been quite popular for microfluidic applications, in particular by academic groups. However, PDMS also has some major downsides that are preventing it to become the material of choice: It is highly hydrophobic and requires surface treatment to make it wettable. A tedious job when dealing with small, high-aspect ratio features. Even though it is inert and non-toxic if sufficiently prepared, it can interact with many chemicals either by swelling or by chemical diffusion into the PDMS. Therefore, PDMS is mostly used only for prototyping or in academic research settings that require many design iterations on small budgets.

Silicon, another common material for microfluidics, doesn’t have the disadvantages of plastics. It is chemically inert, doesn’t swell or let chemicals diffuse in- or out of it. The surface is oxidized at ambient conditions, which provides good wetting characteristics for aqueous solutions. The progress made in semiconductor manufacturing allows to produce very small high-aspect ratio features with high precision.

But silicon has also significant downsides. First, it doesn’t provide transparency in the visible range, which restricts silicon for many applications in the life sciences that use optical analysis, such as microscopy. Second, the economics of silicon is a huge obstacle that prevents broader use in price-sensitive microfluidic applications. The manufacturing techniques for micro-structuring silicon wafers require quite expensive tool preparations and the etching processes are expensive too. Therefore, silicon is typically only used in price insensitive and high-volume applications that cannot be realized with plastics due to the required precision, demanding mechanical properties or chemical inertness.

The third material that is often used for microfluidics is glass. Glass was the most commonly used material in the early days of microfluidics. However, when the required structures become smaller and the requirements for precision and quality increased, the available micromachining techniques weren’t able to meet the demands. Mechanical processes introduce stress and micro-defects in glass, which is problematic for the reliability of experiments. Even sophisticated techniques such as laser ablation with short-pulse lasers cannot avoid these defects. Photolithography on the other side is much more gentle to the material but requires - similarly to silicon - costly and time consuming mask preparations, and only produces low aspect ratio features (wider than deep) because glass etches isotopically. Today, glass is mainly used in microfluidics for shallow structured chips, which are used in large quantities and with a fixed design.

The above mentioned restrictions in manufacturing have prevented glass being used on a much broader scale for microfluidic applications. This is very unfortunate, because glass as a material provides excellent characteristics for microfluidic applications – in particular in the area of life sciences.

Glass is an affordable material with high transparency in the visible region, which makes it well suited for microscopy and other optical analytic procedures. Also, glass is available with low autofluorescence to ensure little background noise for fluorescent techniques.

Chemically, glass is highly inert. It doesn’t swell when brought in contact to organic solvents, and effectively prevents reagent diffusion. The surface is hydrophilic, so aqueous solutions wet readily. The surface properties can be easily adapted by a variety of techniques, such as plasma treatment or grafting procedures, to even incorporate functional chemical groups that enable the binding of various biomolecules, including DNA and proteins.

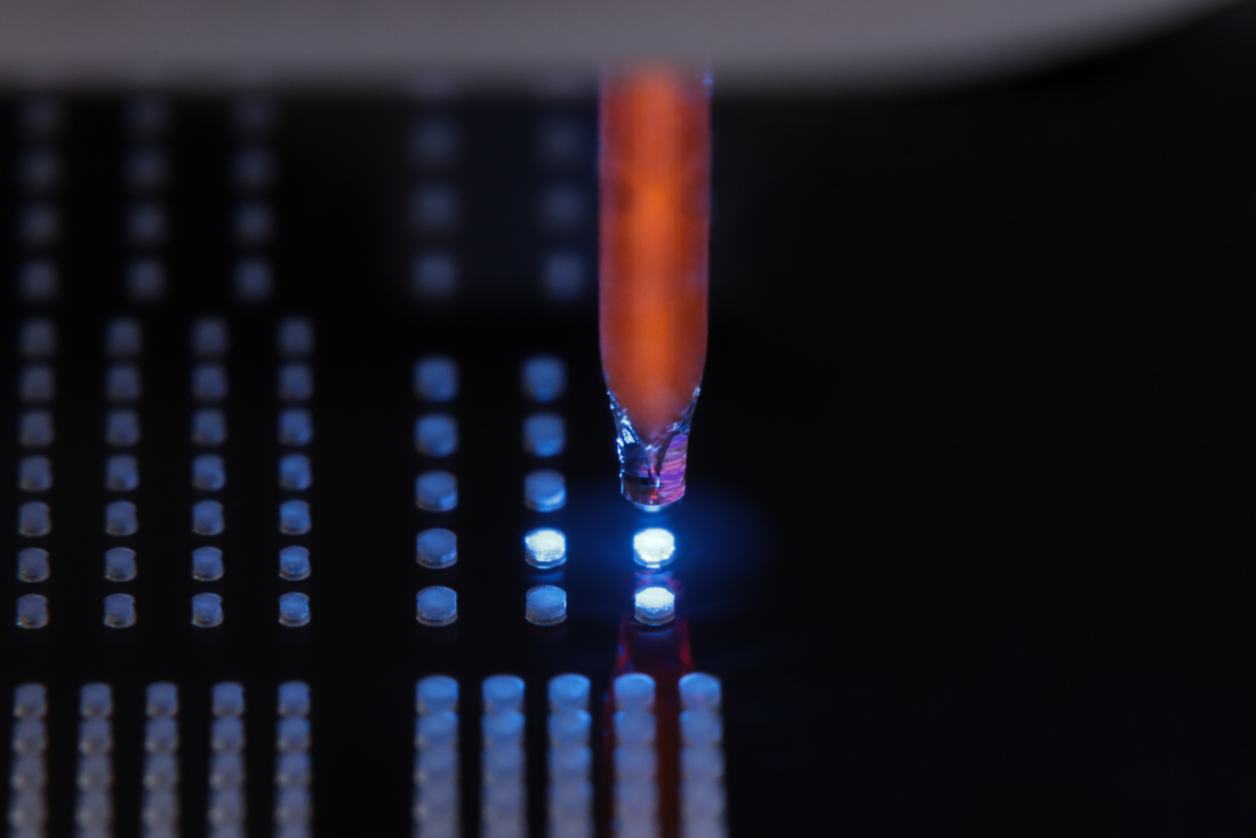

ARRALYZE uses the proprietary Laser-Induced Deep Etching (LIDE) technology to overcome the above mentioned disadvantages of other micromachining techniques for glass. LIDE is a two-step process that can introduce small high-aspect ratio features in the micrometer range into glass without any defects, but with the highest precision. Furthermore, LIDE is a digital manufacturing method, allowing to change designs without the need to produce design-specific and costly tools beforehand. The very fast laser modification step is decoupled from the subsequent material removal by a batch etching process, enabling LIDE to produce microstructured glass with high throughput in an economical manner. These characteristics make LIDE an unmatched micromachining technology to take full advantage of glass as a material for microfluidic devices. Besides the high quality and precision, the ability to produce deep wells in glass is of particular importance for single cell screening applications. For example, shallow micrometer sized wells that share a supernatant do not effectively prevent cells from being inadvertently moved from one well to another by fluid movement or the like. Only deep wells can physically immobilize cells effectively and ensure monoclonality by eliminating the risk of well-to-well cross-contamination. Another very beneficial feature of the LIDE technology is the capability to produce different well types in arbitrary shapes and sizes. This enables to customize the geometry of the microwell plate to the needs of the assay.

In upcoming articles, we will elaborate in more detail about the very crucial feature of deep micrometer-sized wells and the possibilities of customization of ARRALYZE glass chips.